Delays and cost hikes hit Balfour Highlands rail job

Balfour Beatty has been forced to push-back the completion date of its £16m contract to repair the UK’s highest railway.

The Scottish Government’s Highlands and Islands Enterprise (HIE) agency has confirmed the Cairngorm furnicular will not reopen until the “second half of 2022.”

The railway at the ski resort was due to reopen early next year following strengthening work on the 1.9km viaduct that supports the track.

Balfour began work in April 2021 but delays have arisen due to “technical challenges associated with designing and implementing effective solutions to an existing structure, as opposed to a new build.”

Work has also been hampered by the impact of Covid and extreme weather including blizzard conditions in the spring.

HI added that “extra effort has also been required to source vital construction materials that are currently in short supply across the UK.”

HIE interim chief executive Carroll Buxton said: “We’ve always been upfront in describing the reinstatement programme as one of the most complex and difficult civil engineering projects in Scotland.

“As well as managing technical challenges, the team has to take great care to protect the mountain environment, and deal with difficult terrain and extreme weather conditions that can quickly become hazardous.

“The original schedule was very ambitious, even without the impacts of the pandemic lasting as long as they have and before the more recent problems in sourcing construction materials of suitable quality.

“With limited time available to complete these works before winter, postponement has become inevitable.”

The funicular was built by Morrison Construction and opened in 2001 but was taken out of service in 2018 after an engineers’ inspection identified structural defects that raised safety concerns.

Buxton said: “We’re now working with our designers and contractors on a revised schedule for the remainder of the project.

“Harsh mountain conditions mean that all work will need to halt over winter and resume next spring. To ensure safety, there also needs to be a period of testing and certification at the end of the programme, so our current expectation is that the funicular can be relaunched in autumn 2022.

“Clearly, a longer timescale will also have a financial impact. We’ll be reviewing costs very carefully and will publicly confirm a revised budget as soon as it’s possible to do so.”

HIE has also approved up to £780,000 for an extensive refurbishment of the Ptarmigan building that sits on the plateau and includes the UK’s highest restaurant, a shop, exhibition space and viewing platforms.

Following competitive tender, resort operator Cairngorm Mountain (Scotland) Ltd (CMSL) has awarded a contract for the first phase of the Ptarmigan works to Simpson Builders Ltd, based in Beauly. The refurbishment is due to start at the end of August and be completed by the end of 2021.

Did you miss our previous article…

https://www.drupalcamppa.org/?p=221

18 firms win £220m Yorkshire civils framework

Eighteen regional contractors have secured places on a civil engineering framework for the seven councils forming the Yorkshire Highways Alliance including North Yorkshire County Council

The works for complete or part construction and civil engineering work will predominantly take place on bridges and the highway network.

Potential works include: resurfacing, reconstruction, slurry sealing, drainage and kerbing, repairs to bridges, retaining walls and culverts.

Civil Engineering Contractors Framework 2021

Projects £2m+ in North Yorkshire, York, Bradford, Calderdale, Kirklees, Leeds & Wakefield.

C.R. Reynolds; Eric Wright Civil Engineering; Fox (Owmby); Jackson Civil Engineering Group; PBS Construction (North East); Rainton Construction

Projects £500k – £2m in North Yorkshire, York, Bradford, Calderdale, Kirklees, Leeds & Wakefield.

C.R. Reynolds; Colas; Dyer & Butler; Fox (Owmby); Galliford Try Construction; I & H Brown; PBS Construction (North East); Rainton Construction

Projects: up to £500k – Bradford, Calderdale, Kirklees, Leeds & Wakefield

A E Yates; C.R. Reynolds; Cheetham Hill Construction; Hinko Construction; JN Bentley; PBS Construction (North East); Rainton Construction; Seymour Civil Engineering Contractors; Thomas Armstrong (Construction); Thomas Bow;

Projects: up to £500k – North Yorkshire & York

A E Yates; C.R. Reynolds; Cheetham Hill Construction; Hinko Construction; Howard Civil Engineering; JN Bentley; PBS Construction (North East); Rainton Construction; Seymour Civil Engineering Contractors; Thomas Armstrong (Construction)

Plan for major Leeds high-rise student and events scheme

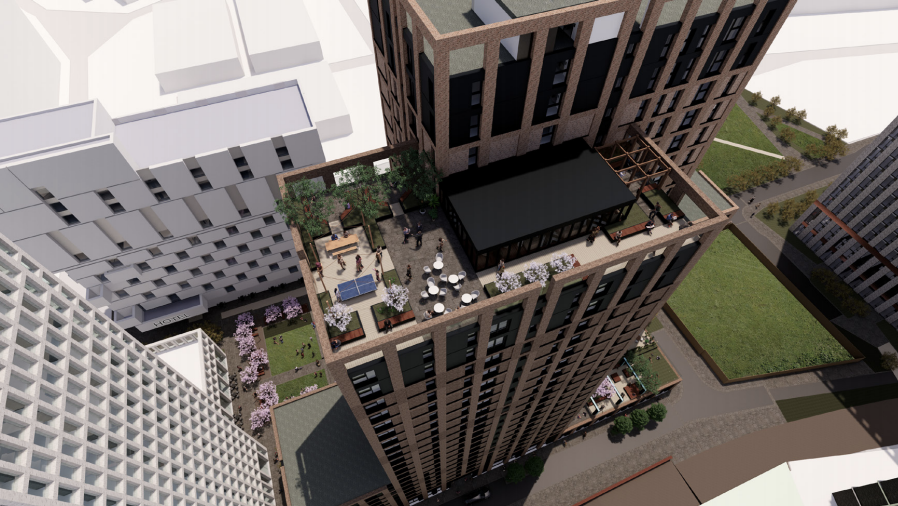

Developer Downing will submit ambitious plans in the autumn for a major student accommodation and events scheme in Leeds city centre, adjacent to the Leeds First Direct Arena.

It will seek detailed planning consent for purpose-built student accommodation across two separate but adjacent plots, and outline planning to develop a multi-purpose events space, which would be taken forward at a future date by Leeds City Council.

A 38-storey purpose-built student tower is planned for Merrion Way featuring 728 student bedrooms in a mix of six-bedroom and 296 studios.

High-rise building proposed for site fronting Clay Pit Lane, Merrion Way and Brunswick Terrace, with nearby events centre plan still at outline stage

Meanwhile, the existing Yorkshire Bank office building would be demolished to make way for the second phase, comprising a stepped building rising to 18 storeys, featuring 543 student bedrooms in a mix of five and six-bedroom clusters and 216 studios.

Second student accommodation building proposal for site located between Clay Pit Lane and Elmwood Close

If approved, the plans will pave the way for 1,200 flats and the creation of a 110,000 sq ft facility including an 800-900 capacity auditorium at the centre of the Leeds Arena Quarter, designed to attract additional corporate, cultural and live events.

The sustainable development will incorporate photovoltaic panels and air source heat pumps.

Each element of the plan promises to regenerate unused space in part of the city that will benefit economically from additional footfall. The proposals also have the potential to create approximately 390 jobs in the construction phase.

George Tyson, projects director at Downing, said: “It has long been recognised that Leeds is in need of an additional, flexible events space capable of hosting corporate banqueting, awards ceremonies and live entertainment. With 2,000 square metre flat floor space, this scheme has the potential to host conferences and exhibitions which can’t be facilitated at the Arena or other venues in the city centre, allowing Leeds to secure business that may otherwise be lost to other cities and regions.”

He added: “Attracting and retaining graduate talent is vital to the health of the regional economy and this relies on being able to offer attractive student accommodation. Our proposals will provide students with brand new, first-class living space in a dynamic part of the city, with fast access to university buildings and facilities.”

Did you miss our previous article…

https://www.drupalcamppa.org/?p=210

Durkan wins Peabody £85m flats job in south London

Housing association Peabody has appointed Durkan to begin construction of a housing scheme in Lambeth, south London.

Over the next three years, Durkan will construct 134 new homes and over 45,000 square metres of commercial space at Higgs Yard, a former industrial site at Loughborough Junction.

Designed by PRP Architects, the scheme represents an £85m investment into the area and will be 50% affordable homes.

It is the largest single development which Loughborough Junction has seen since the Loughborough Estate was built in the 1950s.

Construction on the site is due to begin this Autumn, with completion planned for early 2024.

Tom Williamson, Senior Development Manager at Peabody, said previous plans had been reworked for a better mix of one, two and three-bed homes and incorporate a communal landscaped podium deck at the heart of the development and a roof terrace sitting on the 17th floor.

Ryann Peterson, Head of Bid Management at Durkan, said: Durkan is pleased to have been successful in securing and finalising the contract to deliver Higgs Yard.

This is a very exciting time for us as a business. We’re very much looking forward to continue building on our relationship with Peabody and maximising the potential of this fantastic development.”

Did you miss our previous article…

https://www.drupalcamppa.org/?p=198

Digital Builder Ep 18: 3 Key Takeaways on Prefabrication in Construction

There’s a common misconception around prefabrication—that it amounts to bland, cookie-cutter boxes rolling off an assembly line. But the truth is that prefabrication techniques can allow design teams to produce beautiful, innovative designs that meet the distinct needs of individual clients.

Plus, prefab elements can often be produced more quickly with minimal resources and waste, making it a favorable option for builders and owners alike.

Joining us this week to talk about all things prefab are Nick Coubray, CEO at Howick Ltd., and Amr Raafat, VP of VDC & Technology at Windover Construction. Both guests have extensive experience with prefabrication, and in this episode, we had an interesting discussion on:

The benefits behind prefabrication technology The common myths associated with prefab Some successful real-world examples And how to get started with prefabrication

“Prefabrication combined with other technologies, such as mixed reality, can really enhance the quality of our production in the factory.” — Amr Raafat

(function() { var qs, js, q, s, d = document, gi = d.getElementById, ce = d.createElement, gt = d.getElementsByTagName, id = ‘soun_der’, b = ‘https://embed.sounder.fm’; if (!gi.call(d, id)) { js = ce.call(d, ‘script’); js.id = id; js.src = b + ‘/embed.js’; q = gt.call(d, ‘script’)[0]; q.parentNode.insertBefore(js, q);}})();

powered by Sounder

New Episodes Every Two Weeks

Digital Builder is hosted by me, Eric Thomas. Remember, new episodes of Digital Builder go live every two weeks. You can hear more episodes like this one by subscribing to Digital Builder on Apple Podcasts Spotify Stitcher Google Podcasts, or wherever you listen to podcasts.

You can also subscribe to our email list with the form below so you’re the first to hear when new episodes are released:

MktoForms2.loadForm(“//app-ab10.marketo.com”,”572-JSV-775″,2314,function(form){form.onSuccess(function(values,followUpUrl){var earrings = document.getElementById(‘mktoForm_2314’);

earrings.remove();document.getElementById(‘confirmform’).style.visibility=’visible’;return!1})})>Thank you. We’ll email you the link to the podcast once it’s live..mktoFormSidebar{display:flex!important;justify-content:center!important;flex-direction:column}#mktoForm_2314{display:flex!important;justify-content:center!important;flex-direction:column}#LblEmail{display:none}.mktoFormSidebarTitle{font-family:’Artifakt’!important;font-style:normal!important;font-weight:normal!important;font-size:14px!important;line-height:32px!important;width:fit-content;font-family:’Artifakt Legend’!important;color:#FFFFFF!important;;border-bottom:2px solid rgba(255,255,255,.5)}#mktoForm_2314>div.mktoButtonRow>span>button{background-image:none!important;border:0px!important;background-color:#1858A8!important;font-family:’Artifakt’!important;font-style:normal!important;font-weight:bold!important;font-size:13px!important;line-height:18px!important;text-transform:uppercase!important;color:#1858A8!important}#mktoForm_2314>div:nth-child(3)>div.mktoFieldDescriptor.mktoFormCol>div.mktoFieldWrap>div.mktoLogicalField.mktoCheckboxList.mktoHasWidth.mktoValid,#mktoForm_2314>div:nth-child(3)>div.mktoFieldDescriptor.mktoFormCol>div.mktoFieldWrap>div.mktoLogicalField.mktoCheckboxList.mktoHasWidth{width:auto!important}.mktoFormSidebarText{margin:30px 0;font-family:’Artifakt Legend’!important;font-style:normal!important;font-weight:normal!important;font-size:20px!important;line-height:28px!important;color:#FFFFFF!important}#mktoForm_2314>div:nth-child(2)>div.mktoFieldDescriptor.mktoFormCol>div.mktoFieldWrap.mktoRequiredField,#mktoForm_2314>div:nth-child(2)>div.mktoFieldDescriptor.mktoFormCol,#mktoForm_2314>div:nth-child(2){width:inherit!important}#mktoForm_2314>div.mktoButtonRow>span,#mktoForm_2314>div.mktoButtonRow>span>button{width:100%!important}#mktoForm_2314>div.mktoButtonRow>span>button:after{font-family:’Autodesk-Icon-Font’!important;position:absolute;left:90%;font-style:normal;font-weight:400;font-variant:normal;text-transform:none;line-height:1;-webkit-font-smoothing:antialiased;content:”\e615″}#Email{color:black;background: #ffffff; width:100%!important;padding:0 24px;float:none}#Email::-webkit-input-placeholder{color:black}#Email::-moz-placeholder{color:black}#Email:-ms-input-placeholder{color:black}#Email:-moz-placeholder{color:black}#mktoForm_2314 .mktoButtonRow{display:flex!important;justify-content:center!important}#mktoForm_2314>div.mktoButtonRow>span>button{background-image:none!important;border:0px!important;background-color:#1858A8!important;font-family:’Artifakt’!important;font-style:normal!important;font-weight:bold!important;font-size:13px!important;line-height:18px!important;text-transform:uppercase!important;color:#FFFFFF!important}#mktoForm_2314>div.mktoButtonRow>span{margin-left:0px!important}

3 Takeaways on Prefabrication for Production in Construction

Before diving into the benefits and best practices around prefab, let’s first get clear on what it actually is. Prefabrication refers to the technique of prefabricating assemblies—from whole buildings or entire rooms to much smaller elements and components—in a controlled factory setting. The elements of a building are constructed off-site and then transported to the job site, where they would be assembled.

If you’re curious about prefab and are interested in implementing the practice in your projects, I encourage you to read on. Nick and Amr share their expert takes on prefabrication benefits, myths, and best practices.

1. Debunking common myths about prefabrication

Myth #1: Prefabrication is only impactful for large components or building features

This isn’t necessarily the case. In fact, prefab can also be used to improve the production of a single repeatable feature or very small building elements.

As Amr puts it, “It doesn’t have to be a whole building or a whole room. Prefabrication can be applied to something as small as simple trusses or smaller elements.”

“It doesn’t have to be a whole building or a whole room. Prefabrication can be applied to something as small as simple trusses or smaller elements.” —Amr Raafat

Nick agrees and adds that “Everyone always jumps to volumetric boxes. But like what Amr said, prefab can be applied to something as small as a single component. It doesn’t have to be a fully-finished building and it doesn’t have to be expensive either. It can actually be quite simple, but it’s really about being design-led, rather than actually just making something in a factory.”

Myth #2: Prefabrication only creates unattractive boxes

This is another persistent myth, but untrue. Just because something is made in a factory doesn’t mean it has to be bland or boring.

With the right practices and technologies, you can prefabricate beautifully designed buildings in an efficient and cost-effective way.

“With our prefabrication techniques and our focus on data and technology, we can really produce beautiful designs that could be flexible and respond to client needs,” shares Amr.

He adds, “Our design teams can actually innovate and be more creative in terms of functionality.”

The takeaway? Don’t let old myths and misconceptions stop you from exploring prefabrication. There are a lot of advancements in the realm of prefab that give construction pros more flexibility to design great-looking buildings.

2. Prefabrication unlocks serious production potential

Prefabrication can benefit the entire project and team in a number of ways. Here are the key advantages discussed in the episode.

It saves money. Since prefabrication happens in a factory or manufacturing site, you have more control over your environment, schedule, and timeline. Having a handle on all these things helps minimize unexpected costs.

In addition, prefab enables automation in a factory setting, resulting in fewer errors and labor-hours, so you can keep your costs in check.

No weather delays. Prefab allows projects to be weather-independent. Building something in a controlled environment helps you avoid weather-related and other external disruptions, so projects can be completed faster.

Environmentally friendly. Prefabrication leads to fewer errors and delays, which also means lower energy consumption and less waste — particularly when used with other technologies.

“Prefabrication combined with other technology, such as mixed reality, can really enhance our production in the factory with great quality. What I love about the machinery and the prefab concept is that this machine produces almost zero waste,” says Amr.

Increased quality. Prefab technology and automation guarantees that materials are produced with consistent quality. “Prefab allows you to better control quality. All the BIM data in Revit is carried over into manufacturing, so what you created is exactly what was modeled and approved by the design team,” adds Amr.

Improved safety. Working in a controlled environment means strict safety procedures can be enforced. This is especially important when there are social distancing measures in place. And since the work happens inside a factory site, employees encounter fewer job site-related hazards and unexpected events.

More flexibility. Because components are prefabricated off-site, it’s easier to transport, assemble, and disassemble different elements. This gives you more flexibility when it comes to implementing design changes or relocating materials from one location to another.

3. Start small, but with real projects

Thinking of getting started with prefab? Nick and Amr recommend starting small—but doing it with real projects, so you can learn and improve as you go.

“What I would suggest to people is to start small. Start a single component, like a 2D panel. Then it’s easy to transport to the job site,” says Nick.

He continues, “[with prefab,] the first thing people jump straight to this massive volumetric plant — something like a car factory and a hundred thousand square feet. In reality, what we see is most people begin with a small factory — like a 3,000 square feet facility with a single machine in it.”

“Everyone always jumps to volumetric boxes — or fully furnished units — whereas it can be as small as a single component.” —Nick Coubray

When you’re starting out, you need to ensure that “you have the right data and model,” according to Amr. “You can translate and unify it with manufacturing technologies and techniques.” This is an important consideration as these things will be the foundation of your unified building approach.

Implementing prefabrication successfully requires strong skills and knowledge around BIM and coordination, so it’s recommended to hire team members accordingly. You need the best people who can ensure that all your prefab elements will fit perfectly on-site.

Catch the Full Episode of Digital Builder

Amr and Nick go even further into the ins and outs of prefabrication and how you can implement it successfully. Tune in to the latest episode and discover the best practices and technologies you can use to make prefab work in your business.

Apple PodcastsSpotifyStitcherGoogle Podcastsor wherever you listen to podcasts

The post Digital Builder Ep 18: 3 Key Takeaways on Prefabrication in Construction appeared first on Digital Builder.

Did you miss our previous article…

https://www.drupalcamppa.org/?p=187

Seven win £14bn next-generation Scape frameworks

Scape has named its seven favoured contractors to deliver up to £14bn of projects through its next-generation suite of construction frameworks.

Graham, Kier, McLaughlin & Harvey, Mace, Morgan Sindall, Sisk and Willmott Dixon have been appointed to deliver the Scape Construction framework for England, Wales and Northern Ireland, worth up to £12bn.

In addition, Morgan Sindall, Kier and McLaughlin & Harvey will also deliver the £2bn Scotland Construction framework. Each partner will be supported by an extensive local supply chain.

The overhaul of Scape frameworks sees previous incumbents Lendlease, Robertson and Wates drop out, making way for new commers Mace, Sisk and Graham

Scape frameworks – total spend £14bn

England, Wales & Northern Ireland – Project value £75m+

Mace, John Sisk

England & Wales – Project value: £7.5m – £75m

Morgan Sindall, Willmott Dixon

England & Wales – Project value: up to £7.5m

Kier, Morgan Sindall

Northern Ireland – Project value: £7.5m – £75m

McLaughlin & Harvey

Northern Ireland – Project value: up to £7.5m

Graham

Scotland – Project value £7.5m-plus

McLaughlin & Harvey, Morgan Sindall

Scotland – Project value up to £7.5m

Kier, Morgan Sindall

The four-year net zero-ready public works frameworks will accelerate the delivery of new-build and refurbishment projects of all values from September 2021 and 2025.

With close alignment to the government’s Construction Playbook and a focus on climate action response via the built environment, the suite of frameworks is intended to offer a better way to build and refurbish the public estate, whilst stimulating local economic activity.

The frameworks have been carefully designed to enable clients to benefit from industry transformation, with consideration towards digital construction, platform design and modern methods of construction.

Clients to benefit from several innovative features

A unique parallel lotting structure, offering a choice of two contractors while retaining the free early engagement and direct award.A new lifecycle contract form, supporting clients with energy conservation and the operational efficiency and performance of their assets beyond the construction phase for up to five years. The new feature, which completes the frameworks’ ‘net zero ready’ offer, will help to build and validate a client’s business case for low carbon buildings, and address the historic performance gap between design and in-use building performance.A new commercial model that includes a standard pricing template for greater transparency. Contractors will also commit to 19-day (or better) payment terms for their supply chain partners.Enhanced tailoring of project KPIs and success criteria for every project, leveraging the Construction Innovation Hub’s Value Toolkit to define success for the client.Support from SCAPE’s dedicated framework management team, with performance in delivery measured against market-leading benchmarks for environmental performance, sustainability, social value and the use of local supply chains.

Did you miss our previous article…

https://www.drupalcamppa.org/?p=182

£40m Preston leisure scheme funding deal

Long-awaited plans to revamp Preston city centre with a £40m cinema and leisure complex will finally move to construction after councillors agreed a funding package for the project.

The new development, called ‘Animate’, will be located on the site of the former indoor market and will feature an eight-screen cinema and bowling alley along with five new restaurants and bars, a street-food hub, a car park, and new public square.

The scheme is being developed in partnership with Maple Grove Developments, part of the Eric Wright Group.

Negotiations with anchor operators for the cinema and bowling alley are at an advance stage, alongside strong interest for the restaurant units.

Subject to planning permission being granted, it is anticipated construction work on the project could begin in 2022 with the complex opening in spring 2024.

Councillor Matthew Brown, Leader of Preston City Council, said: “This is a really positive step forward in our plans to bring this exciting development to Preston. The new development will breathe life into the city centre and reinforce the Harris Quarter as a premier cultural and leisure destination in Lancashire.”

Andrew Dewhurst, director of Maple Grove Developments, said: “We look forward to taking the development to the next stage and submitting a planning application this autumn.”

The development is one of six major projects planned under Preston’s Harris Quarter Towns Fund Investment Programme, for which the city was awarded £20.9m from the government’s national Towns Fund initiative in March.

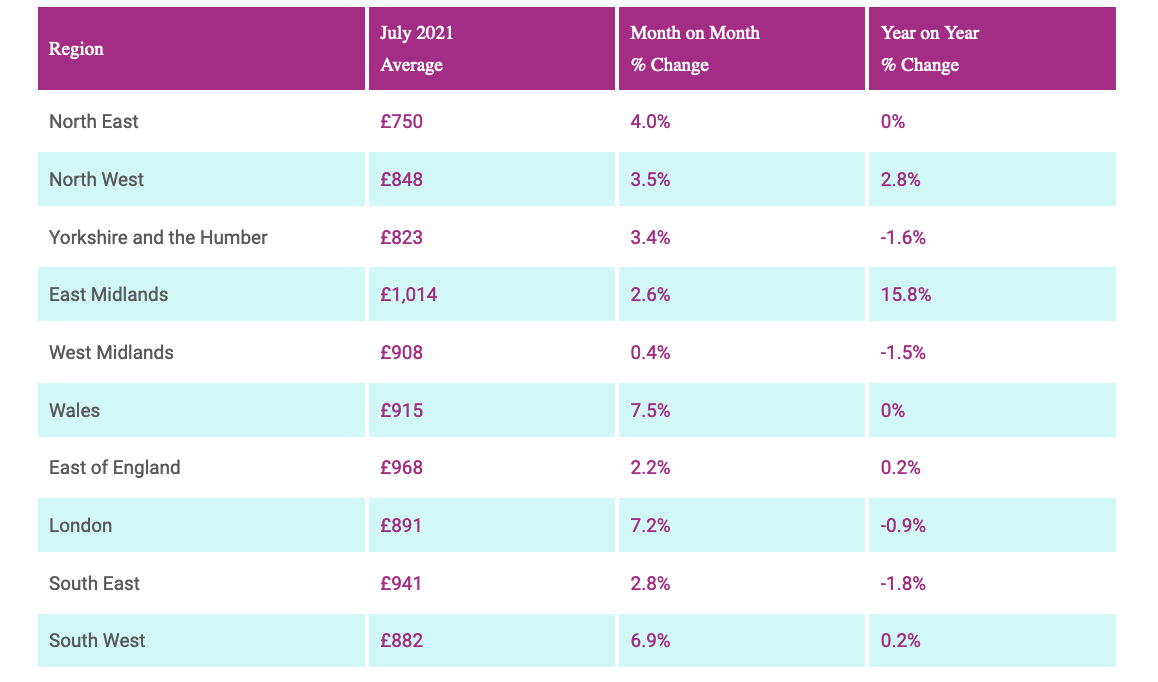

Cost of skilled site labour jumps 3.6% in one month

The cost of skilled labour on site increased by 3.6% last month as inflationary pressures cranked-up in the construction supply chain.

New payroll data from Hudson Contract show average weekly earnings for self-employed tradespeople rose to £904 during July, handing them an extra £124 over the month.

In the East Midlands labour costs hit an all-time weekly high of £1,014 with demand driven by new regeneration, housing and infrastructure projects.

Ian Anfield, Hudson managing director, said: “The housing market is booming with the price of the average UK home increasing by nearly £25,000 over the last year.

“We expect strong demand for new housing and renovation schemes to continue for the foreseeable future. The government is committed to big infrastructure investments as part of its ‘levelling up’ agenda, which is adding to confidence in the sector.

“The challenge for construction firms will be in managing rising costs caused by shortages in building materials and skilled labour.

“We encourage ministers to consider how the industry can increase access to skilled freelancers from Europe under the new immigration system. Self-employed subcontractors make up the most productive and flexible pool of resource in the industry and Britain needs them to deliver these projects on budget and on time.”

Hudson Contract is the UK’s largest provider of tax status and employment contract services to the construction industry and supplies more than 2,500 companies across England and Wales.

Did you miss our previous article…

https://www.drupalcamppa.org/?p=169

Midgard wins £70m Manchester private rental tower

Build to rent specialist Packaged Living has picked JRL-owned main contractor Midgard to build its high-rise scheme of 352 flats in the developing Piccadilly East area of Manchester.

‘The Castings’ scheme consists of four stepped building elements rising to 25 storeys with smaller components at 7, 14 and 20 storeys.

Each building element will have a different coloured brick envelope

The 32-month project to be built on a one-acre site on Heyrod Street near to the planned HS2 station has been designed architect CallisonRTKL, with support from Arcadis, M&E engineer Crookes Walker and Curtins.

It will include a mix of studio, one-, two-, and three-bedroom apartments, as well as 10,000 sq ft of retail and amenity space, a public square and car park.

Hertfordshire-based Midgard will soon start site clearance of two low-rise brick warehouses following approval of its demolition plan.

Mark Woodrow, joint managing director of Packaged Living said: “The Castings is the next exciting BTR scheme in our pipeline, which is now delivering over 3,000 homes in the multi-family sector across the UK.

“The scheme represents a fantastic opportunity to create next-generation homes developed by an experienced team, at a time where vital investment is needed into our city centres.”

Did you miss our previous article…

https://www.drupalcamppa.org/?p=162

Groundwork vets hit by white finger outbreak

Civils contractor Peter Duffy Ltd has been fined £40,000 after multiple employees were diagnosed with Hand Arm Vibration (HAVS).

Leeds Magistrates’ Court heard that the company reported seven cases of HAVS between November 2016 and August 2018.

All of the workers involved had been carrying out ground works involving vibrating tools. Many of them had been working in the industry for over 20 years.

An HSE investigation found that in 2016 the company contracted a new occupational health provider to replace their existing one.

The diagnosis of the workers’ conditions resulted from these changes. Prior to the new company taking over the contract, there was no suitable health surveillance in place to identify HAVS.

Peter Duffy Ltd of Wakefield pleaded guilty to safety breaches and was fined £40,000 and ordered to pay £3,919 in costs.

Speaking after the hearing, HSE inspector Chris Tilley said: “The company should have undertaken a suitable and sufficient risk assessment to identify the level of vibration employees were exposed to throughout their working day and then put in place appropriate control measures.

“Furthermore, the company should have put in place suitable health surveillance to identify HAVS in their workforce.”

Did you miss our previous article…

https://www.drupalcamppa.org/?p=156